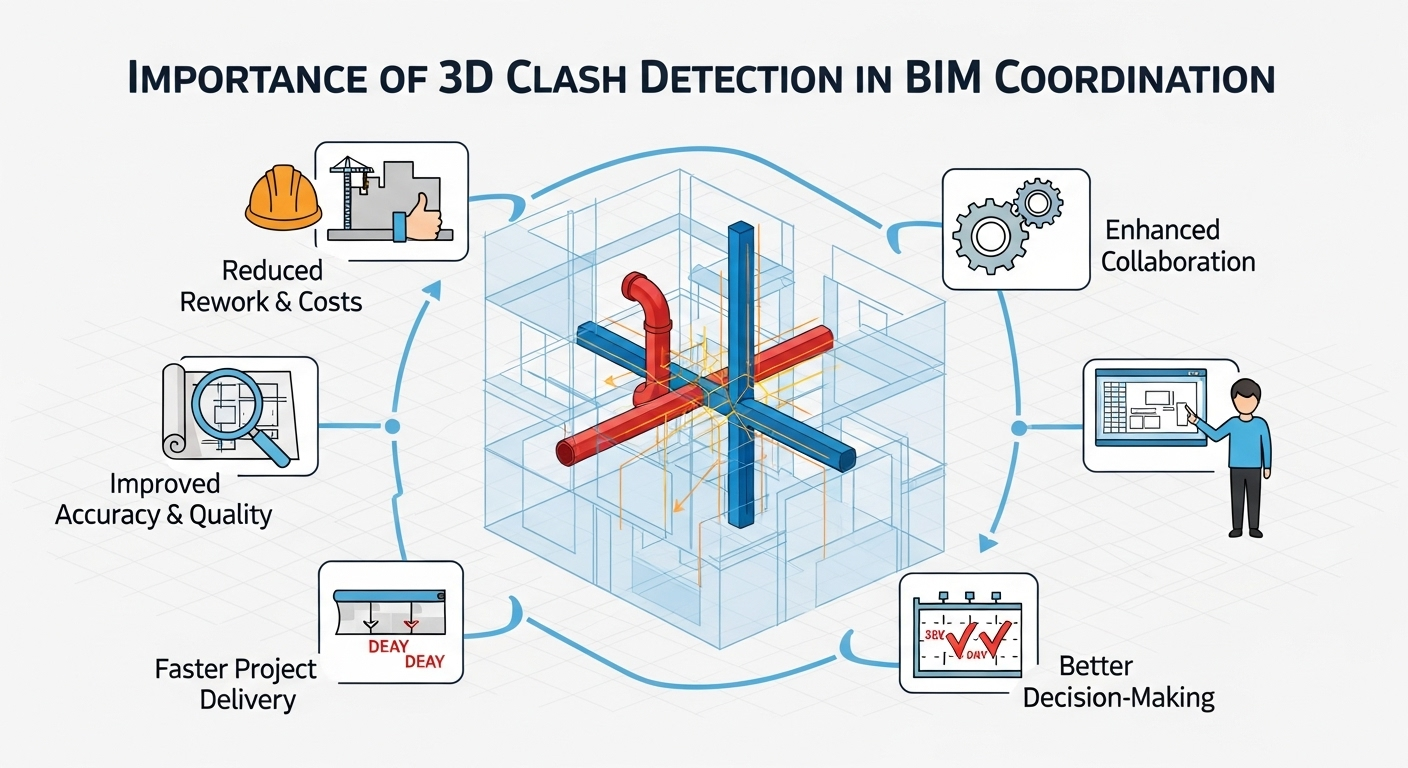

Today’s building projects are more complex than ever. Multiple disciplines—mechanical, electrical, plumbing, fire (MEPF), structural, and architecture—must work together flawlessly. 3D clash detection helps to resolve conflicts before construction begins. BIM model coordination is essential to ensure that all trades work from the same model, reducing errors and delays. Smart coordination is essential in complex MEPF construction to prevent plumbing, HVAC, electrical, and fire systems from clashing. Explore why 3D clash detection in BIM workflows is important, and see how it relates to BIM coordination and the architecture design process.

What is 3D clash detection?

3D clash detection in building information modeling proactively uncovers spatial conflicts between disciplines before construction ever begins. As a BIM coordinator with over a decade of hands-on experience, I run coordinated 3D models through specialized software to flag intersections—for example, HVAC ducts colliding with structural beams or piping routed through walls. By catching these clashes in a virtual environment, we eliminate costly rework and keep projects on schedule.

Why BIM Model Coordination Matters

True BIM coordination happens when all trades share one comprehensive digital design. This collaborative approach reduces guesswork, ensures every element fits together, and prevents the costly surprises that come from relying solely on 2D drawings with hidden collisions.

By bringing architectural, structural, mechanical, and electrical teams into a single model environment, everyone sees exactly where their systems intersect. Mechanical and electrical designers align ductwork, piping, and conduit with the building framework. Structural engineers confirm beam placement around critical MEP runs. Architects maintain their spatial vision without unexpected penetrations.

Benefits of Early Clash Detection

1. Prevent Costly Rework

Redesigning systems to correct problems on-site is a major headache in MEPF construction. The 3D clash detection identifies this problem before hardware is installed or built, saving thousands of dollars in rework.

2. Maintain Project Schedules

The biggest enemy of a project is delay. The project can be kept on track by resolving conflicts during the design phase. BIM MEP coordination helps to maintain timelines and allows trades to work simultaneously without interference.

3. Improve Communication between Teams:

Communication gaps can cause clashes. In a well-planned BIM model coordination, clash reports are exchanged, coordination meetings are held, and resolutions are collaborated on. Transparency builds trust between disciplines.

4. Optimize Designs Early

BIM 3D clash often reveals inefficiencies, such as the opportunity to utilize existing space more effectively. This can result in smarter routings, shorter duct runs, or simpler mechanical layouts.

5. Safety and Compliance Enhancement

Detecting clashes early helps meet code requirements—clearances for fire alarms, emergency lighting, and egress. MEPF construction requires that systems remain accessible and zoned properly, and clash detection can help enforce these standards digitally.

How 3D Clash Detection Fits Into the Architecture Design Process

Clash detection isn’t only for MEP. It began in the architecture design process and evolved as systems were layered in. Typically, here’s how it’s structured.

- Initial Clash Analysis with Architectural & Structural Models: Designers will import architectural columns and structural models into BIM and perform initial BIM coordination between walls, columns, and slabs. This allows designers to catch design-level conflicts, such as beams crossing occupied areas

- MEP integration and BIM MEP coordination: The mechanical, electrical, and plumbing trades overlay their systems on the architectural model. 3D conflict detection then reveals any conflicts between structural components and MEPF.

- Ongoing Coordination

Clash detection is repeated at key project milestones, such as when the architectural or MEP teams update plumbing routes. All teams are kept in sync. - Final Clash Check Before Construction Documents

Before issuing final shop drawings, all disciplines must undergo a final 3D clash coordination test to ensure they are ready for construction.

Tools and Techniques for Clash Detection

Today, BIM platforms such as Navisworks, Revit, and Solibri support advanced clash detection. Features Key techniques include:

- Automated Clash Testing: Create clash rules for categories such as structure vs. systems. The software automatically generates reports on clashes.

- Prioritization and Filtering: Not all clashes require immediate attention. Teams can mark clashes according to their severity, location, or the discipline responsible.

- Visual review: The 3D highlighter makes it easier for team members and managers to understand and locate clashes.

- BIM Coordination Meeting: BIM coordination sessions are held regularly to resolve any outstanding issues. Models are then reimported and checked again once they have been corrected.

- Model Version Control: New models are regularly exchanged to reflect conflict resolutions and avoid the reintroduction of issues.

Integrating MEPF Construction Into BIM Workflows

BIM teams that want to reap the benefits of clash detection must integrate MEPF construction into their workflow.

- Ensure all trades model their systems accurately in BIM-ready formats.

- Definition of clash rules: An early approach to validate system coordination consistently

- Conduct regular coordination reviews to align changes across models.

- Include contractors in the BIM process so that fabrication plans are free of clashes before shop drawings are issued.

By integrating clash detection into the standard processes of BIM and construction, they can work together without friction.

Conclusion

3D clash detection has become a must-have for modern BIM coordination. It allows teams to identify issues earlier, streamline MEP coordination, and integrate electrical and plumbing systems seamlessly into the architectural design process.When BIM model coordination is implemented well using advanced MEPF construction workflows, the result is smoother construction, fewer delays, and safer, cost-efficient projects. Clash detection is essential in a world of collaboration and precision. Teams can ensure that designs not only look great on paper but also work well in real life by adopting consistent practices for clash detection.